Extraction Of Metals From The Ores

Key Notes:

Definition of Ore:

- Ores are naturally occurring rocks or minerals containing sufficient quantities of metal for economic extraction.

Stages in Metal Extraction:

- Concentration of Ore: Removal of impurities (gangue) to increase the metal concentration.

- Methods include:

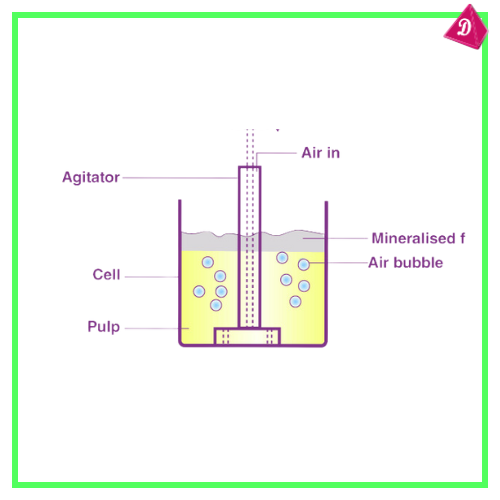

- Froth Flotation: For sulfide ores like copper.

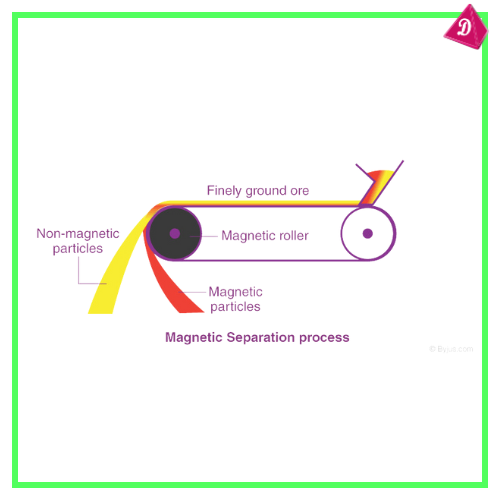

- Magnetic Separation: For ores like hematite (iron).

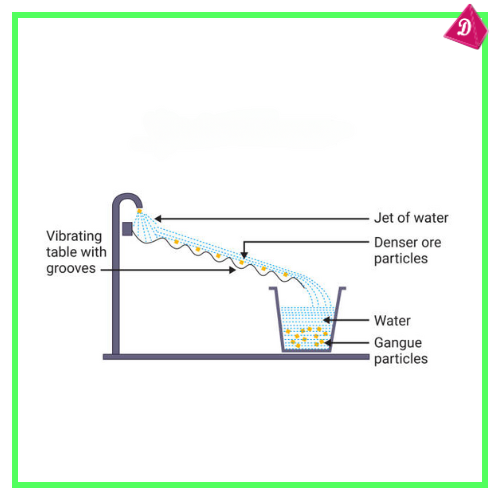

- Gravity Separation: For denser ore particles.

- Methods include:

- Extraction of Metal:

- Metals are extracted depending on their position in the reactivity series.

- Purification of Metal: Removing impurities to obtain pure metal.

Classification Based on Reactivity:

- Highly Reactive Metals:

- Extracted via Electrolysis.

- Example: Aluminium from bauxite (Al₂O₃·2H₂O).

- Moderately Reactive Metals:

- Reduced using carbon or carbon monoxide.

- Example: Iron from hematite (Fe₂O₃) using a blast furnace.

- Less Reactive Metals:

- Found in the free state or reduced by simple methods.

- Example: Gold, silver.

Common Methods of Extraction:

- Reduction by Carbon:

- Used for metals like iron.

- Reaction: Fe₂O₃ + 3CO → 2Fe + 3CO₂.

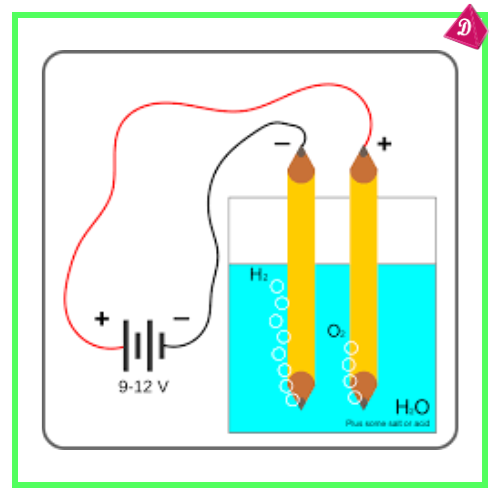

- Electrolytic Reduction:

- Used for metals like sodium, potassium, and aluminium.

- Reaction: 2Al₂O₃ → 4Al + 3O₂ (in a molten state).

- Thermal Decomposition:

- For less stable ores.

- Example: 2HgO → 2Hg + O₂.

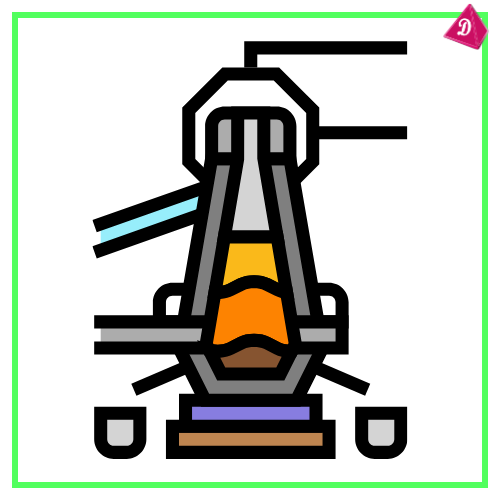

Blast Furnace Process for Iron:

- Inputs: Iron ore, coke, and limestone.

- Outputs: Molten iron and slag (waste material).

- Reaction:

- Formation of CO: C + O₂ → CO₂; CO₂ + C → 2CO.

- Reduction of iron ore: Fe₂O₃ + 3CO → 2Fe + 3CO₂.

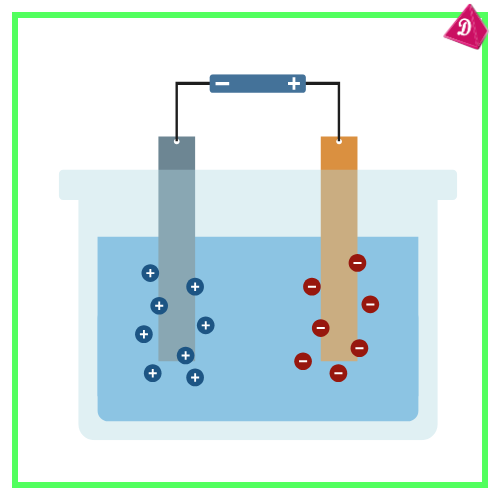

Purification of Metals:

- Impure metals are purified using Electrolytic Refining.

- Example: Copper refining.

- Impure copper is the anode; pure copper collects at the cathode.

Environmental Considerations:

- Mining and extraction lead to habitat destruction, pollution, and energy use.

- Recycling and sustainable methods can minimize environmental impact.

Let’s practice!